1. Scrapper type chip conveyor

A scraper conveyor is a type of flight conveyor. It consists of a trough in which a continuous driven chain with flights is running. The flights are scraping the material over the bottom of the casing. The material is moving forward to the discharge point. Specially designed for small burr handling only. Till date manufacture and installed more than 150 Scrapper conveyors.

2. Hinged belt slat type chip conveyor

The steel belt conveyor is the most versatile of conveyors, it can be used to handle nearly every kind of part and all types of scrap.. Two and one half pitch models handle most applications. Often, four and six inch pitch steel belt conveyors are needed for larger scrap, castings, forgings and any applications with heavy loads or long runs.

3. Screw Conveyor

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a “flight”, within a tube/pipe or U-trough to move powders and granular materials. Screw conveyors and auger feeder are used in many bulk handling industries; in modern industry, it is often used horizontally or at a slight incline as an efficient way to move various materials.

Screw element usually consists of a spiral blade (conveying mechanism is like a screw), which is called flight. Screw conveyor is used for transporting finely divided solids or pasty solids.

Materials having properties such as light-weight, medium-weight, abrasive, non-abrasive, and different densities can be easily handled using a screw conveyor. It is a versatile conveyor system.

4. Magnetic chip conveyor

The magnetic chip conveyor plays a very specific role in chip management – it’s intended for ferrous material applications which produce small chips and fines. The sheet metal belt is stationary, and small ferrous chips are evacuated by powerful magnets rotating underneath the belt. Extensively used for Cast iron / steel / ferrous material Fines / swarf / sludge / small / broken chips Small parts (screws, bolts, etc)

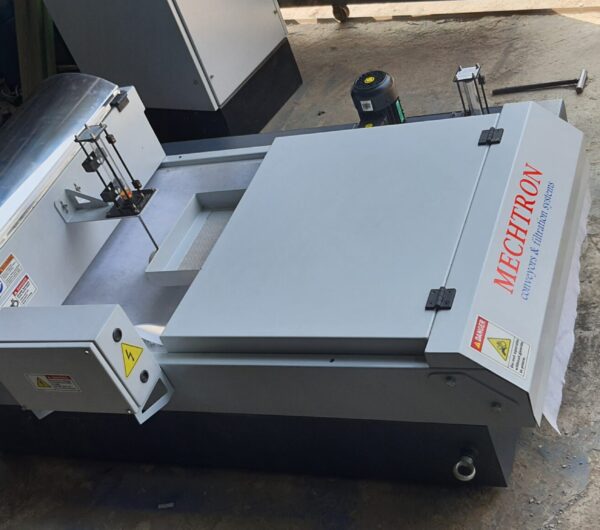

5. Scrapper / Slat type chip conveyor with inbuild drum filtration

- Drum filtration system effectively combines chip removal and coolant filtration. System efficiently removes a wide range of chips and small fines of steel, aluminum, brass and many other materials, to 300 microns nominal.

- Self-cleaning drum system for maintenance free operation.

- Minimal sump maintenance allows for extended coolant life and less down time.

- Drum filter conveyor + hinge conveyor is very proper for dealing with long / short / clip / fine chip.

- Compared to general coolant filtering systems, a separate filtering device is not necessary.

- The degree of chip filtering of a coolant in small area can be improved and consecutive filtering

is possible. - Due to installation of a flushing device to prevent the blockage of a filter, stable coolant supply

is always possible.

1. Compact band filtration system

Compact Band Filters are used for filtration of contaminated coolant coming out of any CNC machine tool. These machines offer better filtration and efficiency compared to standard paper band filters because of the design.

Compact Band Filter is designed to filter ferrous and non-ferrous solid particles from liquid with high degree of purification using paper as filter media to enhance life of liquid and protect surface finish of products. Compact Band Filter works both with water base emulsion coolant as and oil(neat oil). MOC of Compact Band Filter is mild steel, SS-304 and SS-316.

The fluid with dirt is passed to compact band filter through inlet pipe. Float actuated drives motion and indexes dirty filter paper.

- Suitable for fine filtration.

- Filtration capacity.

- Very low maintenance.

- Totally automatic operation.

- Very compact design for individual machine.

- Can be customized to suit your requirement.

- Filtration capacity: 10 lpm to 3000 lpm

Advantages :

- Increase tool life

- Increase surface finish of components.

- Extending coolant life

- Reduces hazards waste

- Cleaner working environment

- Reduces machine down time

2. Gravity Paper band filtration system

These types of filtration units are more commonly used for grinding machines with low filtration volumn and low cost solution. This system used with magnetic separator can give best results for filtration coolant.

3. Coolant tanks with SS Mesh filtration

4 Magnetic Seperators